Our sites

e-Services

- Directory

- Maps and directions

- Reserved services

- Intranet LEPMI

- Portal

Connexion

Connexion

Connexion

Connexion

> Teams > Team EIP > Electrochemical and physicochemical processes

> Teams > Team EIP > Electrochemical and physicochemical processes

During the last decades, the attention has been mostly focused on experimental works. A wide range of architecture and parameter conditions has been studied. However, in order to extend comprehension, to optimize and to scale up the process, modelization is essential. Indeed, mathematical models are able to give a systematic framework to highlight complex mechanism (such as extracellular electron transfer, metabolic reaction, anode geometry, pH and substrate gradient, optimal current production), while limiting costly and time-consuming studies. By using a Nernst-Monod approach, we propose a theoretical model that describes heterogeneous bacteria community and complex substrates influences on biofilm development. Various microorganisms (electrogenic, non-electrogenic and fermentative) and two substrates (acetate, glucose) have been considered. The 1D model calculates local substrates concentrations, overpotentials and pH gradients within the biofilm thickness. The model also shows species spatial distribution. A wide range of species/substrates intrinsic parameters (maximum consumption rate (qmax), half-monod constant (Ks), biomass density (Xf), biomass true yield (Y)) was scanned to define which interspecies competitions could affect MFC behavior (current production, coulombic efficiency, biofilm growth). Besides, we also studied the influence of assumed parameters (biofilm conduction, biomass density, inactivation coefficient and detachment coefficient). The model brings the biofilm spatial heterogeneity to light.

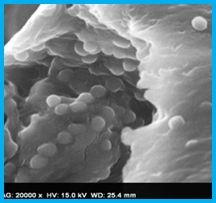

Figure 1 Microbial fuel cell and biological colonization of carbon foam

Recently, the EIP group (electrochemical engendering) leads a project concerning BES development aims at contributing to the energy transition and metals recovering in developing a bioelectrochemical system able to treat both organic containing wastewater, which produces current on anode and uses this one to reduce metals of another liquid effluent on cathode. For these types of BES to be applied in the industrial processes both the entire configuration and unit cells should be scalable, settable, and stackable in series, along with having a low operating cost and be easily service able. The multiphysics approach with bio-inspired design to minimize resistances and to optimize mass and energy transfers significantly contributes to these objectives. Our research group proposes to develop novel carbon foam materials from bio-sourced materials with appropriate properties in order to improve exo-electroactivity of biofilm on anode and metals recovery on cathode: one thesis in progress.

?

Date of update November 15, 2019