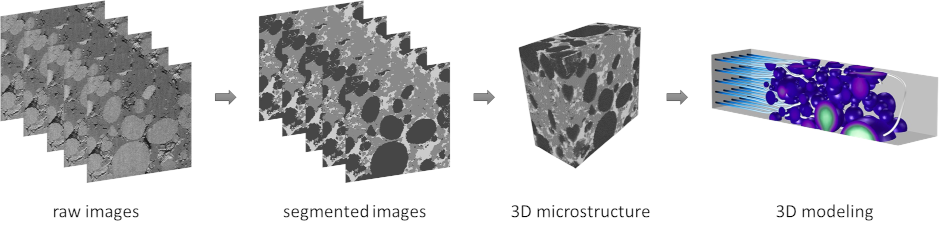

Microstructure reconstruction of porous electrodes

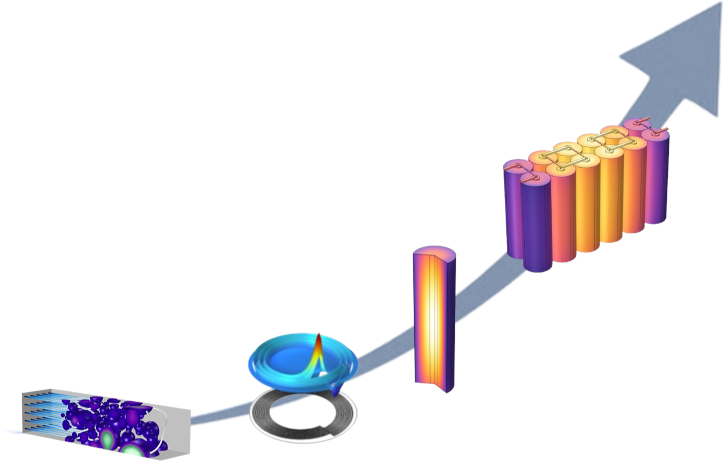

We are interested in the microstructure of porous electrodes in electrochemical systems, such as fuel cells, electrolysers and batteries. Microstructure plays a crucial role in the performance and durability of these technologies. This is because electrochemical reactions occur within these components. It is therefore essential to understand the microstructural parameters of electrodes at the micrometric and even nanometric scale. These parameters include the porosity, permeability and tortuosity of the medium, as well as the size and spatial distribution of catalyst particles and the distribution of the electrolyte (ion exchange polymer) on the surface and within the volume of the electrode, for membrane fuel cells and electrolysers, for example.To obtain this information, imaging techniques are used to distinguish between the different phases. The images obtained are then processed, usually in shades of grey, using specialised software or by developing machine learning algorithms. These processes make it possible to reconstruct the microstructure, which can then be used for simulations. The results of these simulations are valuable for feeding into macroscopic models, thus enabling an effective upscaling to a system approach. These activities are carried out jointly with the MIEL team.

Modelling of an alkaline membrane electrolyser

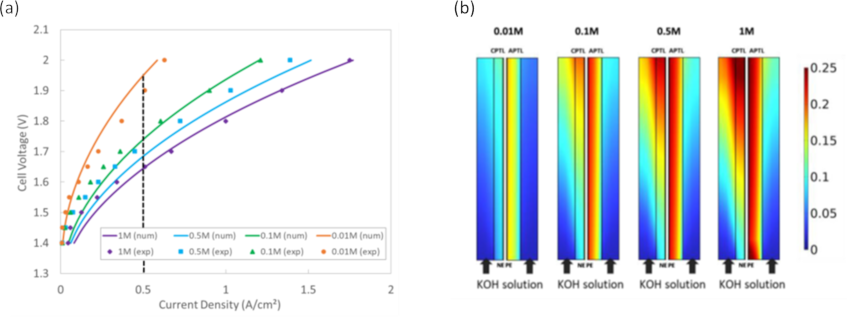

Our team is developing a research focus on modelling material, charge and heat transfer in alkaline water electrolysers with anion exchange membranes (AEMWE). This multiphysics modelling approach aims to deepen our understanding of how this technology works and optimise its performance. Our work consists of designing models that integrate the various physical phenomena involved in a real-world electrochemical cell. These models make it possible to simulate the distribution of physical quantities within the various components, taking into account their geometry and specific material properties.The simulations aim to identify and quantify the physical phenomena that limit performance based on the characteristics and structure of the materials. This work is carried out using COMSOL Multiphysics®, a software package that we have been using for several years to model various electrochemical devices, such as PEM fuel cells and lithium-ion batteries. The results show the influence of the potassium hydroxide electrolyte concentration on performance, as well as the highly non-uniform distribution of H₂ and O₂ gases for current densities above 1 A/cm².

|

|

|

Main collaborations

In the framework of the DuraPEME project (Projet ANR 23-CE05-0002), we are collaborating with the Laplace laboratory (Toulouse) et Femto-ST (Belfort). We are part of the commun laboratory Alcal'Hylab with Michelin.Some publications

Tardy, E., Riasse, R., Vandenberghe, F., Druart, F., Chatenet, M., Bonnefont, A., 2025. Understanding the Operation of a Gas Diffusion Electrode Setup for the Oxygen Reduction Reaction: Experiment versus 3D Multiphysics Modeling. ChemElectroChem 2500172. https://doi.org/10.1002/celc.202500172.

Tardy, E., Bultel, Y., Druart, F., Bonnefont, A., Guillou, M., Latour, B., 2024. Three-Dimensional Modeling of Anion Exchange Membrane Electrolysis: A Two-Phase Flow Approach. Energies 17, 3238. https://doi.org/10.3390/en17133238.

Tardy, E., Thivel, P.-X., Druart, F., Kuntz, P., Devaux, D., Bultel, Y., 2023. Internal temperature distribution in lithium-ion battery cell and module based on a 3D electrothermal model: An investigation of real geometry, entropy change and thermal process. J. Energy Storage 64, 107090. https://doi.org/10.1016/j.est.2023.107090.

Tardy, E., Poirot-Crouvezier, J.-P., Schott, P., Morel, C., Serre, G., Bultel, Y., 2022. Investigation of liquid water heterogeneities in large area proton exchange membrane fuel cells using a Darcy two-phase flow model in a multiphysics code. Int. J. Hydrog. Energy 47, 38721–38735. https://doi.org/10.1016/j.ijhydene.2022.09.039.

Tardy, E., Courtois, F., Chandesris, M., Poirot-Crouvezier, J.-P., Morin, A., Bultel, Y., 2019. Investigation of liquid water heterogeneities in large area PEM fuel cells using a pseudo-3D multiphysics model. Int. J. Heat Mass Transf. 145, 118720. https://doi.org/10.1016/j.ijheatmasstransfer.2019.118720.