This thematic consists in the development of ceramic materials, oxides, or anionic phosphate frameworks in the form of powders and films for their transport or magnetic properties. The optimization of the microstructure and architecture of ceramics via Electrostatic Spray Deposition (ESD) and flash sintering (collaboration with the M2E platform) is one of the strong assets of this thematic. The ESD technique permits to modulate the material microstructures in order to adapt their morphologies to a given functionality and application. Flash sintering allows densification under current conferring microstructures with very interesting properties.

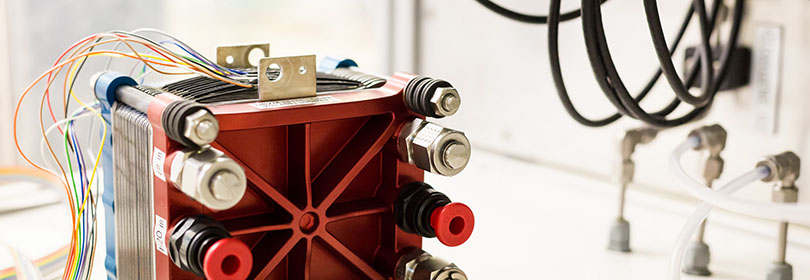

The targeted applications are mainly fuel cells and HT electrolysers, all-solid-state batteries as well as perovskite solar cells and recently medical applications.

Relationships between microstructure/architecture/composition/electrical properties

This activity uses experimental and modelling approaches to optimize the microstructure, architecture and composition of oxygen electrodes used in solid oxide cells operating at intermediate temperatures either in solid electrolyte oxide (SOFC) fuel cells or in high temperature electrolysers (SOEC). The original methodology developed combines an innovative and low-cost shaping method, electrostatic atomization or electrostatic spray deposition, (ESD), electrochemical characterizations and modeling of the microstructure by 3D finite elements (collaboration with SIMAP, CEA Grenoble). This work goes through a key step: the original elaboration by ESD of mixed conduction oxide films (electronic and ionic) with controlled microstructure, either dense or columnar, ~ 10 nm to 10 μm thick, or coral or reticular type, ~ 100 nm to 50 μm thick. The improvement of electrochemical properties has been linked to the intrinsic properties of materials and the development of innovative microstructures and architectures integrating interfaces control. From a fundamental point of view, the influence of tortuosity within a ceramic on its ionic conductivity was demonstrated. The elaboration by flash sintering of cationic conductors was carried out for the first time.

Inorganic electrode materials for Na-ion batteries

This activity focuses on the development and characterization of the structural, morphological, magnetic, electrical and electrochemical properties of new positive electrode materials for Na-ion batteries. Two families were evaluated lamellar oxides NaNi1/3Mn1/3Co(1/3-x)FexO2 and phosphate materials with three-dimensional anionic framework Na2M2M'(PO4)3. The first electrochemical studies of sodium compounds type Alluaudites Na2M2M'(PO4)3,without any microstructural optimization or electrode formulation, have shown the potential of these phases.