From a general point of view, the research activities that are currently being developed can be summarized under the generic title of "Circular systems for the conversion and electrochemical storage of energy: from diagnosis to recycling". These activities are based on our historical skills in chemical engineering (transport, transfer phenomena at interfaces, reaction, electrochemical engineering). In particular, our current efforts are focused on two main points:

The implementation of a reliable diagnosis

Various research efforts currently being carried out by numerous research groups do not always yield methods capable to establish a reliable diagnosis of the ability of an end-of-life battery to satisfy a second use, even if the application is identical (re-use) or different from the first-life application (second-use). The implementation of a reliable diagnosis upon reception of batteries from a first life in order to evaluate their performance is therefore essential. This cannot be done without developing multidisciplinary studies at different scales (materials - cells - pack), namely:

(i) Development of a diagnosis based on acousto-electrochemical impedance spectroscopy.

The acoustic emission has already shown its relevance for the study of batteries, but it is now necessary to go further in the development of this technique. The idea is to develop active acoustic methods, i. e. to subject the battery to acoustic stress and record its response using the principle of electrochemical impedance and to propose ultimately a diagnosis by acousto-electrochemical impedance spectroscopy. This requires both fundamental and experimental work: practical implementation of sensors, signal processing, analysis and correlation with electrochemical mechanisms and the thermo-physical properties of materials. Modelling of thermal, mechanical and electrochemical behavior will also be used to clarify and to refine the comprehension of acoustic impedance measurements.

This work is done in collaboration with CEA-INES.

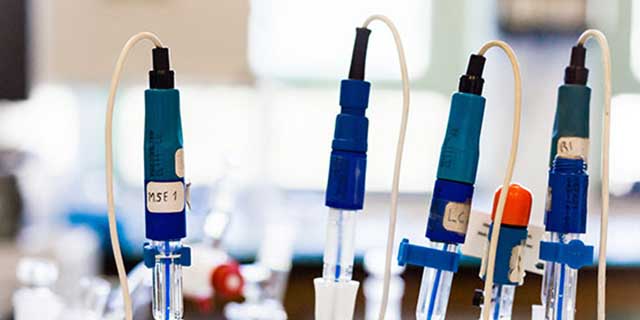

(ii) Use of usual measurements (U, I, T) for a fast diagnosis of the state of health of the batteries.

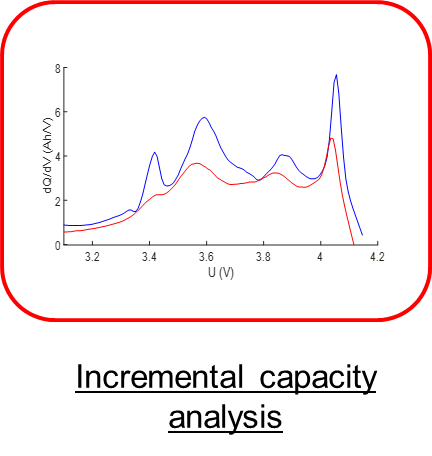

Among the electrochemical methods, incremental capacity analysis (i.e. dQ/dV curves obtained in charge or discharge) also seems to be a good indicator of battery health status. Indeed, the evolution and shift of peaks as a function of battery ageing are signatures of battery degradation. While this method is starting to be used in diagnosis, the links between degradation and signatures have to be imperatively established. This requires a precise control of ageing mechanisms and needs to be coupled with ante- or post-mortem studies using analytical techniques such as tomography, scanning electron microscopy, chemical analysis...

This work is done in collaboration with AMPERE Lyon and G2Elab.(iii) Development of ante- or post-mortem analyses (including in-situ tomography at the commercial battery level) to better understand the mechanisms of ageing.

This work is done in collaboration with CEA Liten and 3SR.The management of second life batteries

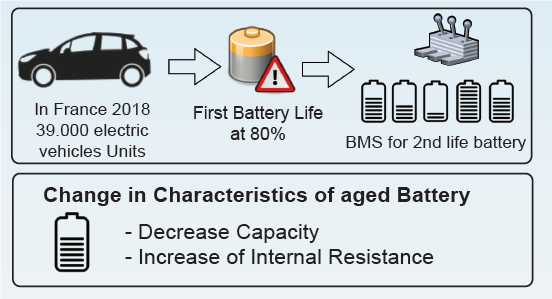

The dispersion of cells, either related to their initial production or resulting from their first life, must be taken into account when re-assembling battery packs. Battery assemblers take care to assemble the least dispersed cells possible when manufacturing a new pack and BMS (Battery Management System) are not designed to accommodate to dispersed cells. The implementation of second life batteries therefore entails additional constraints to be taken into account:

- Management of the original dispersion and ageing in the field,

- Management of second life profiles,

- Management of safety and regulatory policies.

To do this, it is important to develop studies at the battery scale and to couple electrochemical, thermal or electrical engineering approaches:

(i) Realization of small batteries’ packs composed of 3 to 9 cells and study of their behavior in cycling or calendar condition by focusing on the battery architecture (serial or parallel connection) and on the second life profiles (C-Rate, temperature).

(ii) Multi-sensor instrumentation of the packs (temperature sensor, strain gauge, acoustic sensor, reference electrode) to investigate the contribution to the overall battery performance of each cell. The experimental data, thus recovered, coupled with thermo-electrical models, will make it possible to optimize the batteries and manage their temperature and safety.

This activity is part of the establishment policy and is recognised by the Grenoble IDEX through the CIRCULAR project led by G-SCOP, which aims to develop tools for the circular economy by taking batteries as a case study.

This activity is also of interest for industrials (SNAM, Enerstone, Lancey energy storage...) and is carried out with numerous academic collaborations (G2ELAB, G-SCOP, CEA GRENOBLE, AMPERE, INRS CANADA...).