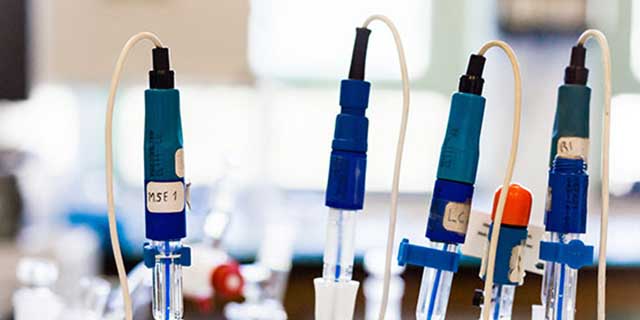

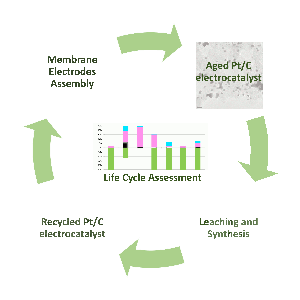

The energy transition requires the development of efficient, carbon-free energy storage and conversion systems. To date, proton exchange membrane technologies (Proton-Exchange Membrane Fuel Cell PEMFC and Proton-Exchange Membrane Water Electrolyser PEMWE) are among the most efficient and mature H2 storage and conversion technologies. A major drawback is the need to use noble metals to electrocatalyse the electrochemical reactions involved in these devices, namely platinum (Pt) and iridium oxide (IrOx). The deployment of these technologies cannot ignore the development of an efficient recycling process. The team is interested in developing environmentally viable processes for recovering Pt and Ir contained in PEMFCs and PEMWEs, whether chemical [1,2,3] or electrochemical [4].

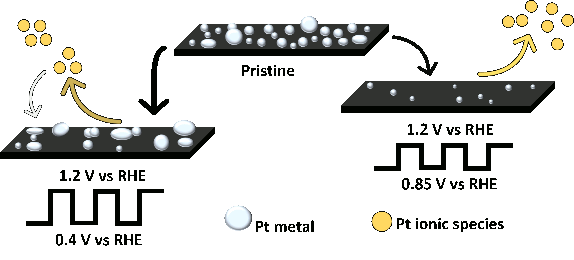

In addition, closed-loop aspects are prioritised. Thus, the remanufacturing of electrocatalysts with specifications equivalent to the state of the art is fully integrated into the studies. This will require a detailed understanding of the physicochemical mechanisms involved in the proposed chemical and electrochemical processes. In particular, the use of in situ and operando methods coupled with electrochemistry makes it possible to identify the optimal leaching conditions for each electrocatalyst based on various parameters (particle size, crystallographic structure, metal oxidation state). This understanding of the leaching mechanism at the atomic scale will lead to the proposal of breakthrough processes for the closed-loop recovery of PEMFC and PEMWE cores, which are necessary conditions for the development of low-carbon technologies while reducing pressure on these natural resources.

In addition, closed-loop aspects are prioritised. Thus, the remanufacturing of electrocatalysts with specifications equivalent to the state of the art is fully integrated into the studies. This will require a detailed understanding of the physicochemical mechanisms involved in the proposed chemical and electrochemical processes. In particular, the use of in situ and operando methods coupled with electrochemistry makes it possible to identify the optimal leaching conditions for each electrocatalyst based on various parameters (particle size, crystallographic structure, metal oxidation state). This understanding of the leaching mechanism at the atomic scale will lead to the proposal of breakthrough processes for the closed-loop recovery of PEMFC and PEMWE cores, which are necessary conditions for the development of low-carbon technologies while reducing pressure on these natural resources.

|

|

| Labex CEMAM project [2] | StackNextGen regional grant [4] |

[1] L. Duclos, R. Chattot, L. Dubau, L. Svecova, G. Mandil, V. Laforest, M. Bolleli, R. Vincent, P. -X. Thivel, « Closing the loop: Life cycle assessment and optimization of a PEMFC platinum-based catalyst recycling process”, Green Chem., 22 (2020) 1919. ⟨10.1039/C9GC03630J⟩. ⟨hal-02473412⟩

[2] T. Bauer, K. Singh, G. Mandil, L. Svecova, L. Dubau, « Identification of the environmental hotspots of a recycling process - Case study of a Pt PEMFC catalyst closed-loop recycling system evaluated via life cycle assessment methodology”, Int. J. Hydrogen Energy, 63 (2024) 393. ⟨10.1016/j.ijhydene.2024.03.023⟩. ⟨hal-04524468⟩

[3] S. Turnbull, D. Clauss, V. Martin, J. -P. Magnin, L. Dubau, F. Maillard, “An Aqua Regia-Free Chemical Recovery and Reprecipitation of Ir from IrOx Catalysts: Optimization of the Extraction Efficiency Using Surface Response Methodology”, RSC Sustain. (2025). (10.1039/D5SU00038F). ⟨hal-04973837⟩

[4] F. Guillet, M. Chatenet, A. Paul, L. Svekova, L. Dubau, « Electrochemical recovery of Pt/C electrocatalyst: optimization of the potential range on the leaching process and application to an aged MEA” Ind. Chem. Mater., Invited article, 2 (2024) 118. ⟨10.1039/d3im00085k⟩. ⟨hal-04245196⟩

[2] T. Bauer, K. Singh, G. Mandil, L. Svecova, L. Dubau, « Identification of the environmental hotspots of a recycling process - Case study of a Pt PEMFC catalyst closed-loop recycling system evaluated via life cycle assessment methodology”, Int. J. Hydrogen Energy, 63 (2024) 393. ⟨10.1016/j.ijhydene.2024.03.023⟩. ⟨hal-04524468⟩

[3] S. Turnbull, D. Clauss, V. Martin, J. -P. Magnin, L. Dubau, F. Maillard, “An Aqua Regia-Free Chemical Recovery and Reprecipitation of Ir from IrOx Catalysts: Optimization of the Extraction Efficiency Using Surface Response Methodology”, RSC Sustain. (2025). (10.1039/D5SU00038F). ⟨hal-04973837⟩

[4] F. Guillet, M. Chatenet, A. Paul, L. Svekova, L. Dubau, « Electrochemical recovery of Pt/C electrocatalyst: optimization of the potential range on the leaching process and application to an aged MEA” Ind. Chem. Mater., Invited article, 2 (2024) 118. ⟨10.1039/d3im00085k⟩. ⟨hal-04245196⟩