Soutenance de thèse de Mme Camille Angelini

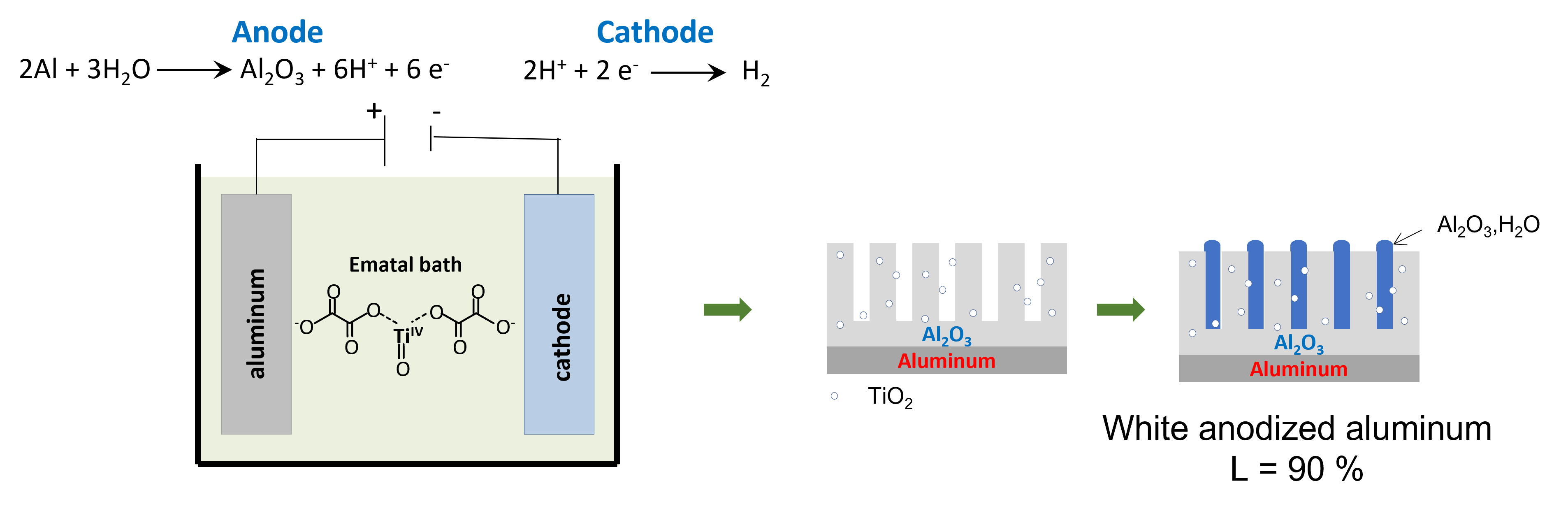

Mlle Camille Angelini soutiendra sa thèse intitulée "Blanchiment de l’aluminium par anodisation en milieu Ematal : Etude des phénomènes mis jeu".

|

Nadine Pébère, Directeur de recherches, CNRS, Rapporteur

Emmanuel Rocca, Maître de conférences, Université de Lorraine, Rapporteur Virginie Roche, Maître de conférences, UGA, Examinatrice Yannick Champion, Directeur de recherches, CNRS, Invité Stéphane Baumhauer, Directeur Technique Société Catidom, Invité Corine Bas, Co-directrice de thèse, USMB Jean-Claude Leprêtre, Directeur de thèse, UGA |

||||||