Abstract : To boost the energy density of lithium-based accumulators, two levers are commonly studied: the energy density and the potential of electrode materials. The use of Li metal as a negative electrode is undoubtedly an appropriate solution to address these challenges since it has the highest gravimetric capacity (3860 mAh/g) and very low reducing potential (-3.04 V vs. Standard Hydrogen Electrode). However, a couple of harmful phenomena prevent from using this ideal negative electrode, such as the dendritic growth during the electrodeposition of Lithium metal when a conventional organic liquid electrolyte is used. As a result, the research has been focusing on the development of numerous solid-state electrolytes (SSE) materials, having high Li+ ionic conductivity, high Li+ transport number, large electrochemical stability window, low cost, recyclable. Despite of breakthroughs for both ceramics or polymers fields (and even composites of both), no room temperature SSE has been developed at industrial scale so far.

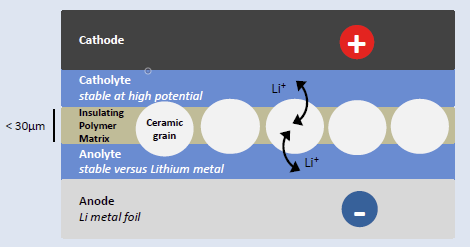

In that context, a new concept of composite polymer/ceramic membrane is studied to be implemented within a Lithium Metal battery. It consists of an electrolytic separator where the Li1.3Al0,3Ti1,7(PO4)3 (LATP) ceramic forms one mono layer of monocrystalline and monodispersed grains bonded with a Poly(ethylene)-based matrix. The LATP grains are the Li+ conducting media allowing the Li+ percolation from one side to another while the Poly(ethylene)-based matrix which is ionically and electronically insulating, and, above all, impermeable to most of conventional Li-ion batteries solvents and Li salts, ensuring both the membrane tightening and very good flexibility. Herein, this composite membrane is elaborated via a low cost, solvent free process thanks to extrusion and calendering which can be industrially upscaled unlike the very complex and multistep processes suggested in the literature so far. The microstructure of the composite separators was characterized by SEM and X-ray Tomography imaging to better understand the influences of the ceramic, the polymer type, and the elaboration process parameters. The Li+ ionic conductivity of the composite membranes as a function of the ceramic content have been studied by electrochemical impedance spectroscopy (EIS) and a high conductivity of 0.49 mS/cm has been measured at 25°C (50vol% LATP). Acting as a chemical barrier, this composite membrane allows the optimization of electrolyte chemistries at both the anode side and the cathode sides. Hence, the ionic charge transfer mechanisms in symmetric electrolyte/membrane/electrolyte systems have been also studied by EIS to determine the driving parameters such as the solvent type, the Li salt type and concentration.

Defense Address : Amphi ouest de l'UFR de Chimie (Batiment Chimie A) : 421 rue de la chimie 38400 Saint Martin D'Hères